How Pallet Flow Rack Can Improve Your Warehouse

As a business unit manager, you know how important it is to always be looking for ways to improve productivity. Improvements are often made through training or utilizing technology, but this is not the only way to increase your efficiency. By investing in pallet flow rack, you will find there are a number of benefits that will help create operational improvements.

Benefits of Pallet Flow Rack on Your Operations

Maximize Your Storage Space

Increase Labor Savings

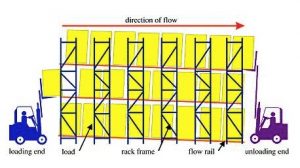

Businesses are always looking for labor savings in today’s tight job market. While traditional selective and drive-in racking require more labor to locate, load, and unload materials, pallet flow racks allow you to reduce the time it takes to store and retrieve pallets. The high-density design of flow racks storage allows for more product storage in a smaller footprint. This reduces the distance forklifts have to travel to load and unload pallets in the racking system.

The way flow racks are loaded from one side and unloaded from the opposite side helps minimize forklift congestion. With less traffic, trips to and from the racks can be completed in a timelier manner.

Improve Your Warehouse Efficiency

Flow racks utilize first-in /first-out (FIFO). FIFO works effectively with the pallet flow racks by allowing forklifts to load the new products on the in-take side of the rack while taking the older products from the other side. This help to ensure proper product rotation, moving the oldest products out before the newer products can be accessed.

Improved Safety

Pallet flow rack can reduce the chance of injury significantly. In a busy warehouse, it can be dangerous for fulfillment employees when forklift drivers are delivering products to the racks using the same aisles as the pickers who are filling orders. When pallet flow rack is integrated into a picking rack system this danger can be greatly reduced. Forklifts are designated for use on certain aisles while fulfillment occurs in aisles on the other side of the racks.

Professional Pallet Rack Installation Services

At Cranston Material Handling, we provide a variety of pallet rack options that we can customize to suit the needs of your business. With decades of experience in designing and building rack systems for our clients, you can expect us to deliver an effective and efficient storage system for your operations.

Contact us today to learn more!