Why Should I Schedule a Pallet Rack Inspection for My Warehouse?

Pallet racking is an integral part of warehouse operations and material storage throughout a plant. Damage can occur to your racking at any time and when it happens, it compromises the safety of your employees. No matter the type of business or product you store, it is important to have an inspection and maintenance plan in place for your pallet racking.

Damaged Racking Can Easily Go Unnoticed

Damage to the racking system is commonly caused by forklifts loading and unloading the racking or traversing through the system. Factors such as high traffic in the system, narrow aisles, poor forklift operator training, and changes in the product stored can put your racking at a higher risk of damage.

It is common for a damaged rack to be left in service either because the damage seems minor and is not addressed or the damage simply goes unnoticed by the untrained eye. By having your pallet rack system inspected by a professional, damage to your racking can be identified and addressed in a timely manner before it becomes a major hazard.

Inspections Can Help Reduce Employer Liability

Safety in the workplace is a very high priority for companies, but when racking is not well-maintained, you risk not only causing damage to materials that fall but also injuring employees. If an accident or a major event such as a rack collapse, were to occur due to damaged racking, your company could be held liable for not resolving an unsafe condition.

Keeping your pallet racks maintained through regular inspections should be part of your facilities planned maintenance. Thereby keeping your employees safe and reducing your liability, if an accident were to occur.

Schedule a Professional Pallet Rack Inspection with Cranston

Although it may be tempting to inspect the racking on your own, using a professional rack inspector with the experience to know what to look for is the best way to ensure that damaged components are identified. This allows you to receive a report that details what actions need to be taken to maintain the structural integrity of your system.

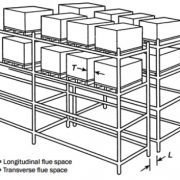

During a pallet rack inspection, Cranston Material Handling Equipment will thoroughly inspect each component of the racking to check for any bent, missing, or broken parts and to see if the safety clips or bolts are in place and properly engaged. The components that are examined include:

- Anchors

- Baseplates

- Safety guards

- Uprights

- Beams

- Wire deck or pallet supports

- Safety bolts and safety clips

The racking is also examined to ensure it is being used and loaded correctly. Once the inspection is complete, a detailed report is generated noting what components are damaged and if any of the pallets were loaded incorrectly. Recommendations for repair, replacement, or other corrective measures will also be made.

Contact us today to learn more about our pallet rack inspections services and how we can help you create a safer work environment.