Tips on Selecting and Installing your Pallet Rack

Pallet racking is a common and popular storage solution in distribution centers, manufacturing facilities, and warehouses of all sizes. With a wide range of pallet racking choices, it is essential to understand the flow of your pallets to and from the racks, the type of pallets you are using, and the type of loads or SKUs you are storing. This will allow you to choose the style of rack that will provide you with the best solution for your needs.

At Cranston Material Handling, our team will listen to you and work with you to understand your needs and develop the right storage solution for your business. We will ask the right questions so that we have the information to properly layout your rack system in the most beneficial, cost-effective manner possible.

When you decide to move forward with purchasing a pallet rack system from us, our team will go through many steps to ensure we layout and design a system with the appropriate options, so your storage needs are met.

Design and Layout Services for Your Pallet Rack System

Our team will come to your facility to get an accurate understanding of what you need to store and to see the area where the racks are to be installed. Once we have assessed your needs and goals, we will evaluate what style of racking is most appropriate for your specific requirements.

The type of racking systems that we will consider include:

Selective Pallet Rack

This type of racking is the most common racking style with the lowest cost per pallet position. This racking is the most versatile and accommodates the widest variety of product sizes.

Double Deep Selective Rack

This type of racking can increase storage capacity by as much as 40%. However, it lacks direct access to all the pallet positions and requires a double deep reach truck to access the back pallet.

Comparison of Push-Back, Drive-in, and Flow Rack

Push-Back Rack

This type of pallet racking uses a Last-In/First- Out system that works well for operations that have a high volume of product but a limited number of pallets per SKU or freezer applications. This type of racking stores pallets one to six pallets deep. Keep in mind with this type of racking system to function properly it is important to have consistent pallet weights, pallet design, and uniform pallet loads.

Push-back racking offers dense storage of like SKUs but does not have direct access to each pallet. Push-back is a great option if you produce or ship products in batches. It is highly popular where dense storage is required because it is more efficient than Drive-in rack because the forklifts do not have to drive into and then back out of the system to store and retrieve each pallet. It is also far less expensive than Pallet Flow Rack.

Drive-in Rack

This type of racking works on a Last-In/First-Out system and works great when there are large quantities of similar SKUs or freezer applications. The pallets are stored on horizontal rails that run from the front to the back of the system. Pallets must be in excellent condition and uniform in width. Drive-in rack provides the greatest density of storage possible at the lowest cost.

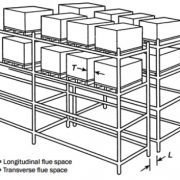

Pallet Flow Rack

This type of racking works on a First-In/First-Out system which works great for material that has expiration dates and freezer storage. Flow rack offers convenient solutions for storage of like SKUs. Careful consideration must be given to the weight and design of your pallets. It allows for the greatest pallet density possible. It is a highly efficient system, as manufacturing loads the racks on one side and shipping unloads the racks on the other side of the system.

Choosing Between Roll-formed and Structural Style Racking

Most systems can be purchased in either style. Roll-formed has a lower initial cost and installs more quickly. After installation the beam levels can be adjusted more easily. Structural rack can have much higher capacities and lower maintenance costs. Durability and damage resistance are structural racks significant advantages. Some manufacturers will guarantee their structural racks will not damage.

At Cranston Material Handling, we will evaluate your pallets and warehouse space as we work with you to choose which style of rack best suits your application. We will then develop an efficient rack layout to provide you with the greatest storage capacity and the most productive material flow possible.

Expert Project Management and Installation Services

When you are ready to install your new pallet racking system, our team will work with you to coordinate the delivery and installation. To prepare for the installation we will meet with you to ensure all parties understand the scope, timeline, ship dates, final layouts, and sequencing of the installation. We will track the delivery of the system’s components that will be arriving from several manufacturers. We will keep you updated and be available to answer questions as they arise.

If you do not have the personnel available to install the pallet rack, allow Cranston Material Handling to perform the installation for you. We offer expert installation services for all the products we distribute. Using our experienced employees or subcontractors with specialized skills, we can ensure efficient, quality installation of your pallet rack system. Contact us today to speak with one of our material handling experts to learn more about our wide range of pallet rack systems.