Tabletop Chain Conveyors

Tabletop chain conveyors, also known as flat top chain conveyors, are the reliable and efficient workhorses in the material handling world. Imagine a smooth, flat surface propelled by a sturdy chain – that’s the essence of these versatile systems. They shine in diverse applications, handling various products efficiently and reliably.

What are Tabletop Chain Conveyors?

These conveyors feature a continuous chain with a flat top plate, creating a stable platform for transporting a wide range of goods. They come in various configurations, offering flexibility to tackle diverse needs.

Types of Tabletop Chain Conveyors:

- Straight-running: Classic design for linear product movement, ideal for packaging lines and assembly applications.

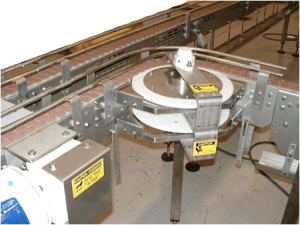

- Side-flexing: Offers the ability to navigate curves and tight corners, enhancing flexibility in complex layouts.

- Open top: Standard chain with exposed top plate, suitable for various product shapes and sizes.

- Closed top: Enclosed top plate, ideal for applications requiring easy cleaning and dust-free environments.

Benefits of Using Tabletop Chain Conveyors:

- Versatility: Handles diverse products, from bottles and cans to packages and individual items.

- Smooth handling: Minimizes product damage and ensures stability during transport.

- High capacity: Capable of handling substantial product volumes, boosting efficiency.

- Flexibility: Offers straight and curved configurations to fit various layouts.

- Durability: Robust construction ensures long-lasting performance in demanding environments.

Choosing the Right Tabletop Chain Conveyor:

Selecting the perfect system requires careful consideration of several factors:

- Product characteristics: Size, weight, and shape of goods to be transported.

- Throughput requirements: Desired speed and volume of product movement.

- Layout constraints: Straight or curved path needed, and available space.

- Cleaning considerations: Open or closed top, and ease of cleaning procedures.

- Budget: Balancing initial investment with long-term benefits.

Get A Proposal

Additional Considerations:

- Product spacing: Offers precise product spacing and accumulation capabilities for specific needs.

- Motor type and speed control: Variable speed options for flexibility and energy efficiency.

- Safety features: Pinch point protection, emergency stops, and guardrails for operator safety.

- Integration with other equipment: Compatibility with palletizers, depalletizers, and sorting systems.

Invest in Smooth and Efficient Product Handling

Tabletop chain conveyors offer a practical and reliable solution for various material handling challenges. From their diverse capabilities and efficient product movement to flexible configurations and robust design, they provide a valuable asset for businesses seeking to optimize their operations.

Ready to explore the benefits of tabletop chain conveyors? Contact Cranston Material Handling to discuss your specific needs and find the ideal tabletop chain conveyor system for your product handling requirements.