Food-Grade / Sanitary Conveyors

For businesses in the food and beverage industry, maintaining hygiene and sanitation is paramount. That’s where Cranston Material Handling’s food-grade conveyors come in, acting as the silent heroes that ensure safe and efficient product movement without compromising quality.

What are Food-Grade Conveyors?

Food-grade conveyors are specialized systems designed to transport food products while complying with strict hygiene and safety regulations. They differ from standard conveyors in several key ways:

- Materials: Constructed from non-toxic, non-absorbent materials like stainless steel or FDA-approved plastics, minimizing contamination risks.

- Design: Featuring smooth, crevice-free surfaces and easy-to-clean components for thorough sanitation.

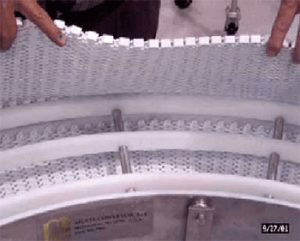

- Belts: Utilizing food-grade belting resistant to bacteria growth, wear, and tear, often with open weaves for enhanced drainage.

- Compliance: Meeting stringent regulations set by organizations like the FDA, USDA, and NSF for safe food handling.

Types of Food-Grade Conveyors:

- Belt Conveyors: Versatile and popular, featuring continuous belts for various products like fruits, vegetables, and packaged foods.

- Roller Conveyors: Cost-effective for lighter items like bakery goods or packaged snacks, offering easy cleaning and inspection.

- Chain Conveyors: Durable for heavier loads like meat carcasses or large containers, providing stability and sanitation.

- Spiral Conveyors: Space-saving option for multi-level food processing, minimizing floor space with efficient vertical transport.

Benefits of Using Food-Grade Conveyors:

- Enhanced Food Safety: Reduce contamination risks with compliant materials, design, and sanitation practices.

- Improved Efficiency: Automate product movement, increasing processing speeds and optimizing production flow.

- Reduced Costs: Minimize product waste and rework due to contamination, maximizing yields and profitability.

- Simplified Cleaning: Streamline sanitation with easy-to-clean surfaces and minimal crevices for improved hygiene.

- Regulatory Compliance: Ensure adherence to food safety regulations and avoid potential penalties or recalls.

Choosing the Right Food-Grade Conveyor:

Selecting the ideal food-grade conveyor system requires careful consideration of several factors:

- Type of food product: Ensure the conveyor safely handles your specific product dimensions, weight, and temperature requirements.

- Production volume: Choose a system with sufficient capacity to meet your daily processing needs.

- Cleaning procedures: Select a conveyor compatible with your sanitation protocols and frequency.

- Layout and space constraints: Opt for a conveyor that integrates seamlessly into your existing facility layout.

- Budget: Consider the initial investment, ongoing maintenance costs, and potential long-term cost savings from improved efficiency.

Get A Proposal

Additional Sanitary Conveyor Considerations:

- Automation features: Explore options like speed control, product accumulation, and sorting for increased functionality.

- Washdown capabilities: Choose a system designed for high-pressure washdowns for thorough sanitation.

- Spare parts and maintenance: Ensure easy access to parts and readily available support for smooth operation.

Invest in Safe and Efficient Food Handling with Food-Grade Conveyors

By implementing the right food-grade conveyor system, you can transform your food processing operations. From ensuring food safety and regulatory compliance to improving efficiency and reducing costs, food-grade conveyors offer a valuable investment for any business in the food and beverage industry.

Ready to elevate your food safety and efficiency? Contact Cranston Material Handling – call 412-858-8416 today to discuss your food-grade conveyor requirements.

About Cranston Material Handling

Cranston Material Handling of Pittsburgh, Pennsylvania is known for offering the highest level of professional consultative sales and service of industrial equipment, project management and equipment installation in Southwestern Pennsylvania.