Choosing Wire Decking for Your Storage Rack

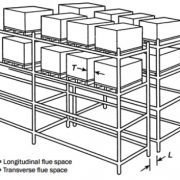

For decades, pallet racks have played an important part in increasing and maximizing the storage capacity of distribution centers and warehouses. An essential part of pallet racking design is the rack decking. This decking serves as a base for storing non-palletized items or cases in conjunction with palletized products.

Decking increases overall warehouse safety by increasing the number of contact points between the product that is being stored and the storage media to reduce the chance of products falling. Like with any part or product, not all types of decking are created equally. A commonly-used and highly versatile option is wire decking.

Benefits of Using Wire Decking

- Easy to Install. Wire decking does not require any tools for installation. It merely needs to be dropped into place and sit flush with the beams.

- Unbeatable Strength. Wire decking with channel supports can support more than 2,500 pounds of materials.

- Increases Overall Safety. Wire decking increases safety in the event of a fire by allowing the water to fall through the mesh and eliminating the need to have in-rack fire protection systems. With a small surface area, wire decking doesn’t accumulate as much dirt and debris as solid wood or steel deckings do, so it requires less routine cleaning to stay in compliance with local safety and health laws.

How to Choose the Best Wire Decking

Once you’ve decided that wire decking will work best for your distribution center or warehouse, you will need to choose which type of wire racking will work best. When choosing wire decking for your application, consider the following:

What are you storing?

When selecting wire decking, the weights and overall dimensions of the products or materials that will be stored are the most critical factors. Keep in mind that wire decking is not intended to support the entire weight of a pallet or point load unless it was explicitly designed to do so. If it was not designed to do so, it can warp or collapse under the pressure, creating a significant safety risk.

What type of storage media will the wire decking be installed in?

Do you plan to use the wire decks for bulk shelving? Pallet racking? If you plan to use the wire decks for pallet racking, then you need to consider whether it is structural or roll-formed. The overall dimensions of beams and uprights can differ among manufacturers, so you must check the sizing to ensure they fit correctly.

How do plan to use the wire decking?

Do you plan to store individual pieces of equipment? Loose cases? Or full pallets? While pallet racking can support all of the above, it is important to consider how you plan to use the decking in your design overall.

Wire decking is commonly used to store individual cases. If you intend to use your wire decking for this purpose, then it is important to consider increasing the density of the wire mesh grid. Standard grid densities include:

- 2”x 4”

- 2.4”x 4”

- 2.5”x 4.5”

When using the wire decking to store individual cases, you should select a grid size of 1”x2” or 1”x4”. Design enhancements tailored to your specific application can also be included in the wire decking. For instance, the waterfalls, the 90-degree turn at the front and rear edges of the decking, can be arranged upwards to prevent products from sliding off the deck. You can also add on accessories like dividers to help keep products organized.

What type of environment will the wire decking be used in?

Another essential factor to consider is the environment the wire decking will be exposed to. Do you plan to use the wire decking in a freezer or cooler? Will it be used outside or in a facility to store food? For most applications, a paint finish of baked on or powered-coated enamel will suit your needs. In environments where oxidation or moisture could be a concern, stainless or galvanized steel should be considered.

The position of the wire deck channels should also be considered based on the environment the wire decking will be used in. Many times, the wire deck channels need to be inverted or flipped upside down. When you invert the wire decking channel, you can help alleviate the buildup of moisture, dirt, dust, and other debris. In industries like the food industry, this practice can help promote a more sanitary environment.

Choosing the right wire decking for your pallet rack system may seem like a simple process, but there are a lot of factors that go into making the right selection. Once you’ve decided on the type of decking, like wire mesh, you still need to consider your entire application to ensure that it will serve as the best solution for your facility.

Cranston Material Handling has decades of experience in designing pallet rack systems and assisting customers in finding the best storage solutions to meet the needs of their application. Contact us today to speak with one of our material handling experts to learn more about our wide range of pallet rack systems and other available storage solutions.